Understand the global mainstream certification marks of magnetic materials and downstream products-2

8. Japan PSE certification

PSE is a certification mark given by Japan for electronic and electrical products that comply with Japanese safety regulations. According to the Japanese Electrical Appliances and Materials Control Law, 498 products must pass safety certification to enter the Japanese market, which is a mandatory market access system for electrical appliances in Japan.

PSE includes EMC electromagnetic compatibility and safety requirements. All products in the "Specified Electrical Appliances" catalogue that enter the Japanese market must pass the certification of a third-party certification body authorized by the Ministry of Economy, Trade and Industry of Japan, obtain a certification certificate, and There is a diamond-shaped PSE logo on the label.

9. Australia SAA certification

SAA certification is a certification under the Standards Association of Australian, so many friends call the Australian certification SAA. Due to the mutual recognition agreement between Australia and New Zealand, all products certified by Australia can enter the New Zealand market smoothly.

All electrical and electronic products sold in Australia must undergo safety certification (SAA). There are two main types of SAA logos, one is formal approval and the other is standard logo. Formal certification is only responsible for samples, while standard marks are required for each factory inspection.

10. Australia C/A-tick certification

C/A-tick certification is a certification mark issued by the Australian Communications Authority (ACA) for communications equipment. A-Tick is only applicable to communication products, and most electronic products apply for C-Tick. However, if you apply for A-Tick for electronic products, you do not need to apply for C-Tick separately. Australia's EMC electromagnetic compatibility system divides products into three levels. Suppliers must register with ACA and apply for the C-Tick mark before selling level two and level three products.

11. Australia RCM certification

RCM is a unified identification mark for electrical products being introduced in Australia and New Zealand. The mark is a trademark owned by regulatory agencies in Australia and New Zealand, indicating that the product meets both safety regulations and EMC requirements and is non-mandatory. RCM certification can only be applied for by a local company in Australia, and the company must apply for an RCM number from the Australian government. Chinese manufacturers and exporters can apply for IEC or AS/NZS reports in their own names, but the reports must be submitted to Australian importers to apply for RCM.

12. German GS certification

GS is the abbreviation of Geprufte Sicherheit in German (safety certified), and it also means "Germany Safety" (German Safety). GS certification is based on the German Product Safety Law (GPGS), and is a voluntary certification for testing by TÜV, VDE and other institutions authorized by the German Ministry of Labor to test in accordance with the EU unified standard EN or German industrial standard DIN. It is recognized by the European market for German safety. The certification mark is a safety mark accepted by the majority of customers in Europe.

The GS certification mark applies to a wide range of products, mainly for products in direct contact with people. For electrical products, household electronic equipment, electrical and electronic office equipment, communication products, power tools, industrial machinery, laboratory measurement equipment, etc.

13. German VDE certification

The full name of VDE is VDE Testing and Certification Institute, that is, the German Electrical Engineers Association. It is one of the most experienced testing certification and inspection institutions in Europe. As an internationally recognized safety testing and certification organization for electronic appliances and their components, VDE enjoys a high reputation in Europe and even internationally. The range of products evaluated includes household and commercial appliances, IT equipment, industrial and medical technology. Equipment, assembly materials and electronic components, wires and cables, etc.

14. China Taiwan BSMI certification

BSMI is the abbreviation of Bureau of Standards, Metrology and Inspection in English of the Bureau of Standards, Metrology and Inspection of the Ministry of Economic Affairs of Taiwan. According to the announcement of the Ministry of Economic Affairs of Taiwan, from July 1, 2005, products entering the Taiwan area will be subject to electromagnetic compatibility and safety regulations. China Taiwan BSMI certification is mandatory. It has requirements for EMC and SAFETY. However, BSMI currently does not have factory inspections, but it must act in accordance with the regulations of the Bureau of Standards. Therefore, BSMI's certification model is: product inspection + registration supervision.

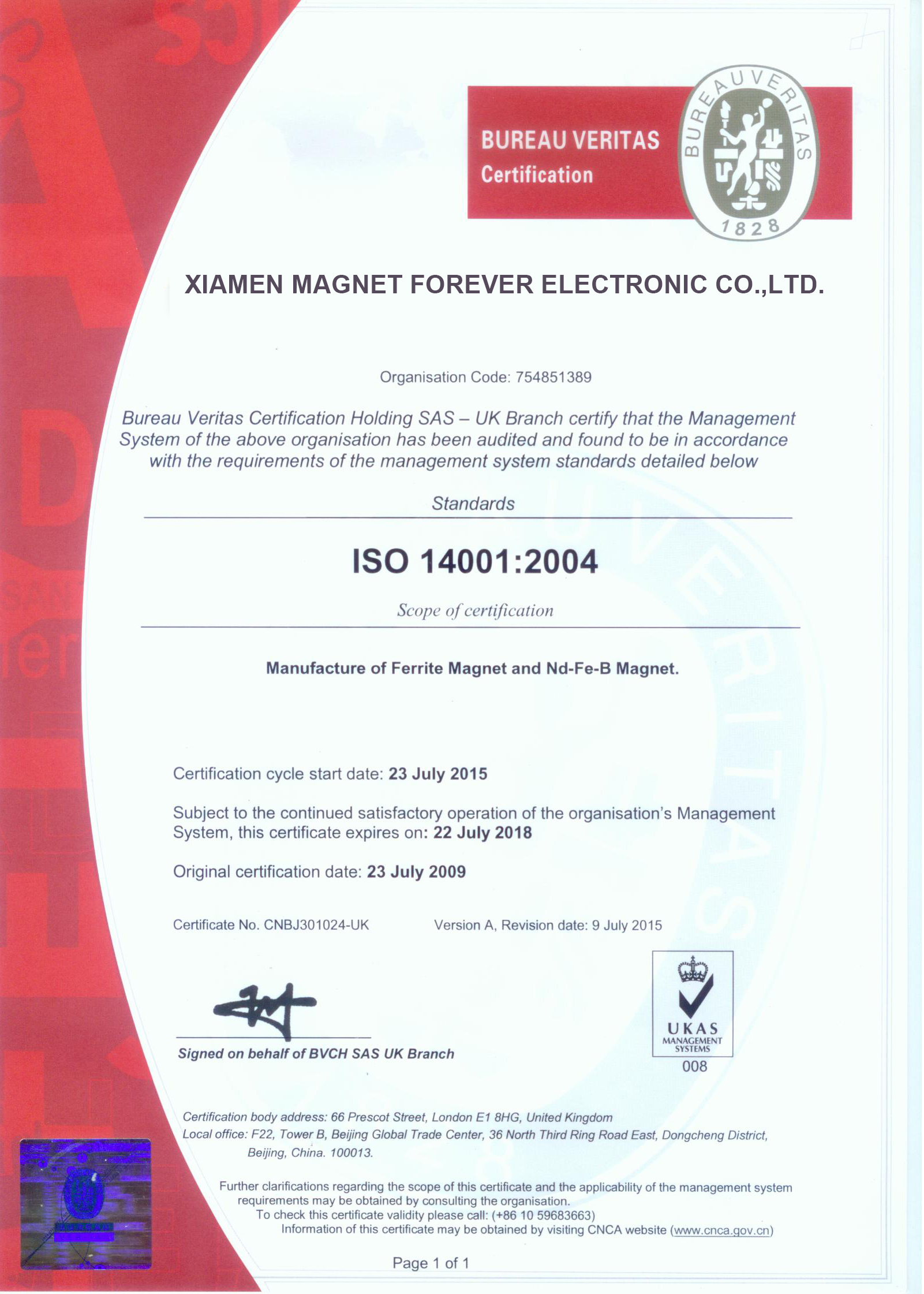

15. ISO9000 and ISO9001 quality system certification

ISO9000 is a quality management system and a set of standards. The standards include 4 core standards:

ISO9000:2005 Quality Management System-Basic Principles and Terminology

ISO9001: 2008 Quality Management System-Requirements

ISO9004: 2009 Quality Management System—Guidelines for Performance Improvement

ISO19011: 2011 Quality and Environmental Audit Guidelines

Among them, the most commonly used is the ISO9001 quality management system requirements, and the object of its certification is the supplier's quality system. The object of quality system certification is not a certain product or service of the enterprise, but the quality system itself. Of course, the quality system certification will inevitably involve the products or services covered by the system. Some companies apply for the certification of the overall quality system including all types of products or services of the company, and some applications only include one or part of the product (or part of the product). Service) quality system certification. Although the scope of products involved varies greatly, the objects of certification are the quality system of the supplier. Quality system certification is often required by the supplier in order to provide quality assurance to the outside world, so the certification is based on the relevant quality assurance model standards.

Magnet Forever offers you more professional magnet knowledge