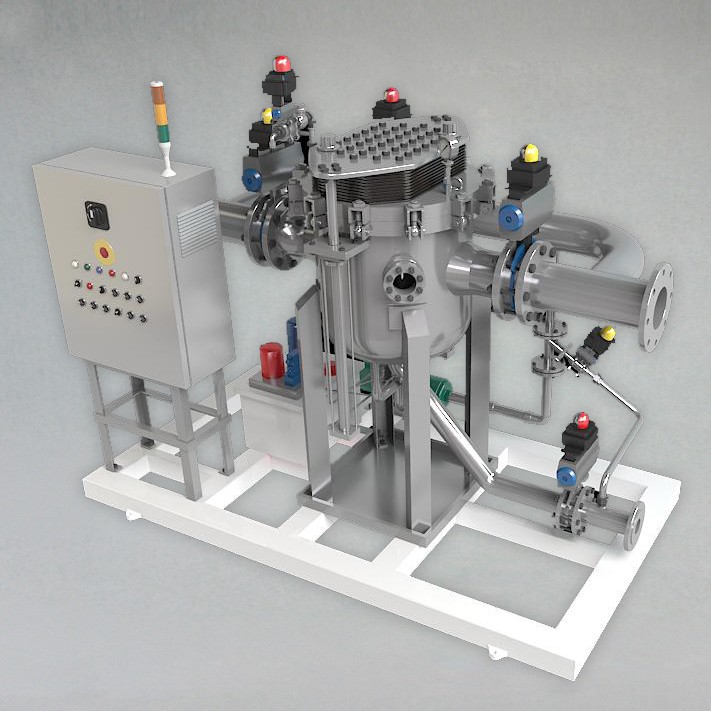

Magnetic filter Filtration introduction

The magnetic filter can meet the technological requirements of liquid media, so it is widely used in the food industry, medicine, cosmetics, fine chemical industry and other industries. One group of filter devices is put into operation, and the position of the reversing valve is changed when cleaning, and the other group can be operated continuously, which can ensure the continuity of the process pipeline.

product description:

The magnetic filter is made of a combination of a strong magnetic material with high coercivity and a blocking filter. The adsorption force is ten times that of general magnetic materials. It can absorb micron-level ferromagnetic pollution under instantaneous liquid flow impact or high flow rate. It can also overcome the ferromagnetic pollutants washed down under high-speed and large impact and be absorbed again, thereby avoiding the jamming of hydraulic components or the wear caused by friction, extending the service life of hydraulic components and hydraulic systems, and enhancing hydraulic pressure. The reliability of the system. Its center is a cylindrical permanent magnet, and the outside of the magnet is a cover made of non-magnetic material. There are several iron rings around the cover, the iron rings are connected by copper bars, and a certain gap is maintained between each iron ring. When the ferromagnetic impurities in the hydraulic medium pass through the iron ring gap, they are adsorbed on the iron ring to filter out. In order to facilitate cleaning, the iron ring is divided into two halves. When the gap is blocked by impurities, the iron ring can be removed for cleaning, and then installed and used repeatedly. The magnetic filter element can also be combined with other filter materials to form a combined filter element for the paper filter element filter on the oil return line. Among them, the filter paper filter element is made by bonding the inner and outer cylinders and the oil filter paper sandwiched in between. The inner and outer cylinders are rolled by thin steel plates, and the plates are punched with many oil-passing holes; the filter paper is folded into a star shape to increase the flow area. The central rod of the filter element is equipped with a magnetic filter element composed of many magnetic rings and nylon spacers.

In recent years, with the increasing development of my country's automobile industry and home appliance industry, most domestic automobile and home appliance manufacturers have begun to pay more and more attention to the surface cleanliness of steel plates. The two main production processes that affect the cleanliness of the strip surface are strip cold rolling and degreasing cleaning. During the cold rolling of strip steel, in order to lubricate and cool the rolls, the surface of the strip and rolls are sprayed with emulsion (the main component is rolling oil); on the other hand, due to the grinding of the rolls on the surface of the strip, a large amount of iron will be produced. Powder, and adhere to the strip steel. However, in the cold rolling production process, using suitable rolling oil and optimizing the rolling process, the use of sodium hydroxide-type cleaning agent in the degreasing cleaning section can easily remove the residual rolling oil, and iron powder due to its inherent characteristics It is difficult to remove, so the control and removal of the amount of residual iron powder on the surface of the strip is a difficult point in the control of the cleanliness of the surface of the strip. Practice has proved that in the cold rolling production and degreasing cleaning process, there are more methods and methods to control and remove the amount of residual iron powder; in the cold rolling production, select the appropriate rolling oil and reasonably distribute each rack (or each channel). Second) The reduction rate, the chrome plating of the roll and the working mechanism of the magnetic filter, etc.; and in the degreasing process, select the appropriate degreasing fluid, strengthen the brush roller bristles, adjust the cleaning temperature and speed, and the working mechanism of the magnetic filter.