Eddy Current Losses of Rare Earth Permanent Magnets in Motor Applications

Both samarium cobalt and neodymium iron boron are metal materials. Due to the good electrical conductivity of metal materials, the resistivity is very low, which is not a good thing for rotating machinery such as motors, because it will bring eddy currents of rotating machinery. loss, causing heating of rotating machinery, including magnets. Therefore, magnet eddy current losses that occur in rotating machinery are a must for magnet and motor designers. Today, I will take you to understand what is the eddy current loss of magnets and how to avoid eddy current loss in the production of magnetic materials.

To understand and reduce eddy current loss, we should first know how eddy current loss is generated. Here we need to introduce a concept - skin effect (skin effect)

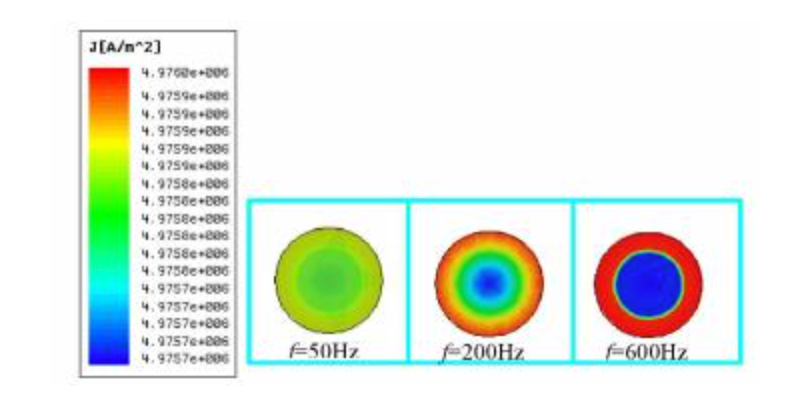

When the alternating current passes through the wire, the distribution of the current density on the cross-section of the wire is uneven. The phenomenon is called the skin effect.

The cause of the skin effect is the eddy current. From the law of electromagnetic induction, an alternating magnetic field will be generated around an alternating electric field. When an alternating current passes through a conductor, an alternating magnetic field will be generated in and around the conductor, causing a vortex-shaped induced current inside the conductor. Eddy current is referred to as eddy current. .

The closer it is to the center of the conductor, the higher the induced electromotive force generated by the alternating magnetic field in the conductor, the stronger the eddy current, and the stronger the obstruction to the original current, resulting in a smaller current density approaching the center of the conductor, while approaching the surface higher current density.

Since the induced electromotive force increases with increasing frequency, the skin effect also becomes more pronounced with increasing frequency. When a high-frequency current passes through the wire, it can be considered that the current only flows in a thin layer on the surface of the wire, which is equivalent to reducing the cross-section of the wire, which greatly reduces the effective utilization of the conductor material.

Eddy current loss

Since the resistance of samarium cobalt and NdFeB permanent magnets is relatively small, the eddy currents in the alternating electric field are generally relatively large. Due to the thermal effect of the current, the eddy current will make the magnet heat up, and thermal demagnetization will occur when the temperature is too high.

The magnitude of eddy current loss is related to factors such as the way the magnetic field changes, the motion of the magnet, the shape of the magnet, permeability and resistivity. The higher the rotational speed (equivalent to frequency) and permeability of the rotating machinery, the lower the resistivity, the smaller the skin depth, and the greater the loss caused. In electric vehicles, elevators and other fields, in order to control the speed, the permanent magnet motor is usually controlled by the inverter power source. Due to the existence of high-order harmonics of the carrier frequency, the eddy current loss in the magnet will also increase and cause thermal demagnetization.

Reducing Eddy Current Loss of Sintered NdFeB by Improving Resistivity

From the point of view of motor design, in order to reduce the eddy current loss of permanent magnets in rotating machinery, several technical methods have been proposed, such as shielding columns surrounding the magnets, methods of dividing the magnets and isolating the magnets on the side, etc.

From the perspective of magnets, one of the most effective ways to reduce the eddy current loss of the motor is to use bonded magnets. Because of the presence of the binder and a sufficiently high volume fraction, the resistivity of the bonded magnet is 102~104 that of the sintered magnet. times, but the power and maximum operating temperature of the motor are greatly limited, so the most direct method is to increase the resistivity of the sintered magnet itself.

There are many ways to improve the resistivity of sintered magnets, such as adding powders with high resistivity (Al2O3, etc.), coating SiO2 coatings, etc., but these methods will affect the magnetic properties of sintered magnets to a certain extent. Therefore, in the research and development of magnets A balance needs to be made between resistivity and magnetic properties in the process.